After much anticipation, Apple finally announced that they have been developing a smartwatch to compete with the likes of Pebble, Motorola, and Samsung. In his keynote, Tim Cook revealed that the back of the watch is made of a ceramic material called Zirconia (also known as Zirconium dioxide).

Why did Apple choose to make the back of their watch from Zirconia? Let’s take a look..

1. It’s all to do with the charging. To make charging the watch as easy as possible, and to make the design as clean as possible, Apple has opted to go with inductive charging. Devices that use inductive charging must have a non-conductive section that will not interfere with the wireless charging. This means that metal could not be used on the back of the watch.

2. Motorola chose to use a plastic back on its Moto 360 smartwatch that also features inductive charging, however, Apple is known for its products being made of premium materials. Zirconia can be polished to a beautiful finish and has been used in premium watches for years.

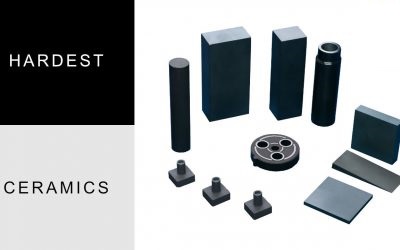

3. Zirconia has very favorable mechanical properties and has often been called “ceramic steel”. Those super sharp and ceramic knives you see being sold as superior to steel – those are Zirconia. Of all the potential ceramic options that Apple could have used in this application, Zirconia makes the best sense because it offers excellent wear resistance and decent toughness. Just don’t drop it.

There you have it – Zirconia was a natural choice for Apple when they needed a material that was not electrically conductive, has a premium feel, and offers mechanical properties that can withstand the daily abuse a watch receives.