DuraShock™ (B4C/SiC) – Ceramic Armor

Key Properties

- Improved impact behavior

- Consistently performs above similar hybrids

- Lightweight for ballistic protection applications where pure Silicon Carbide is too heavy

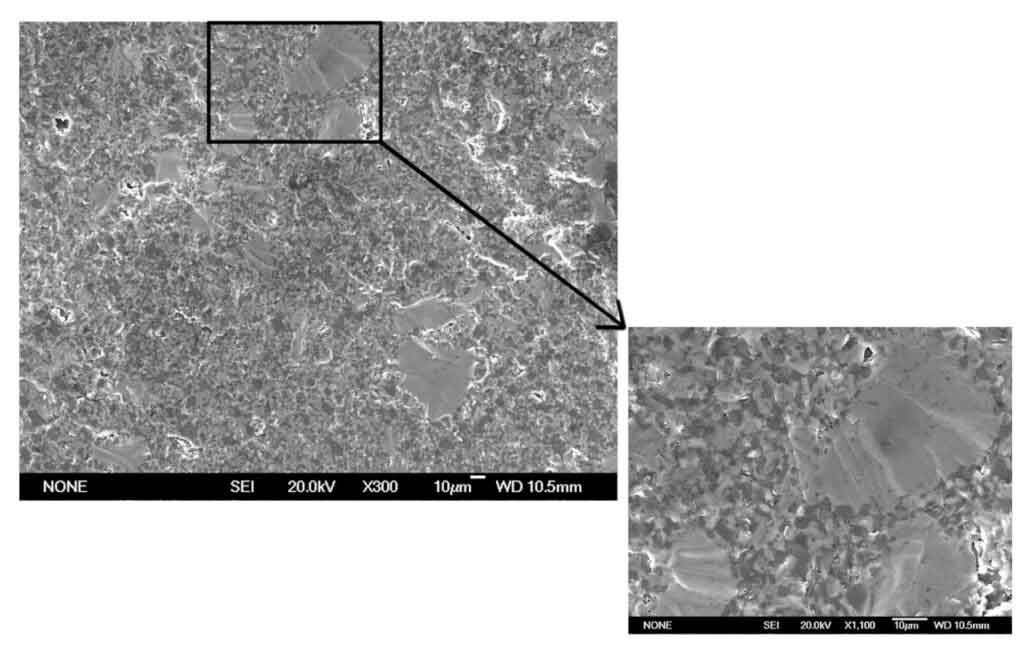

- Unique microstructure with aggregated SiC provides toughening by crack deflection

- Price competitive against traditional pure Boron Carbides

- High hardness, low density, high melting point, high elastic modulus, chemical inertness

- High neutron absorption cross-section

- Excellent thermoelectric properties

- Consolidation by pressure less sintering – economical process with ability to form complex shapes

- Further densification possible without changing the material characteristics

- All allow for complex shapes and access apertures to be easily incorporated, even in small batch quantities

Applications

- Bullet Resistant Armor Plates

- Body Armor

- Helicopters Panels

- Lightweight Vehicle Protection Panels

Material Properties

Density

Unit

Value

Hardness HV0.5

Unit

Value

Toughness KIC

Unit

Value

* KIC Toughness as measured by the indentation method.

Disclaimer: The values presented are mean and typical of those resulted from test samples. They are provided as an indication only to serve as guidance in the design of ceramic components and are not guaranteed in any way. The actual values can vary according to the shape and size of the envisioned component.

DuraShock™ Under the microscope

- Silicon Carbide aggregates – the key behind crack deflection and exceptional ballistic properties

- Superior performance vs. all other tested hybrids

- Only surpassed by hot pressed Boron Carbide

- Can potentially protect against WC cored threats

Related Materials

Boron Carbide

DuraShock™ & DuraWear™

Boron Carbide (B4C), also known as black diamond, is the third hardest material after diamond and cubic boron nitride. It is a suitable material for many high performance applications due to its attractive combination of properties.

Silicon Carbide

CeramaSil-C™

Silicon Carbide (SiC) is one of the lightest, hardest, and strongest technical ceramic materials with exceptional thermal conductivity, acid resistance, and low thermal expansion.

Frequently Asked Questions

- Why is ceramic used in body armor?

The combination of low specific weight, high hardness and reasonable toughness makes it a great material for body and vehicle armor. The weight reduction achieved with lightweight ceramics like DuraShock™ vs. steel or heavier ceramics is substantial and allows the vehicle to take on more cargo or ammunition. For these reasons it is a popular alternative to steel armor and offers extra comfort and flexibility in body armor allowing the wearer to move more freely.

- What is DuraShock™ ceramic armor made of?

DuraShock™ is a Boron Carbide/Silicon Carbide ceramic composite, developed to give the very best combination of high ballistic performance with weight saving considerations while maintaining a reasonable cost. It’s a material developed and sold by China Ceramic Parts.

- What is the difference between DuraShock™ and other ceramic armor?

Both Boron Carbide and Silicon Carbide are excellent armour materials in their own rights , each with advantages and disadvantages. For example Boron Carbide is very light and provides a very good level of protection but its brittle and very expensive to manufacture. Silicon Carbide is more economical to produce, but it’s heavier and it’s performance is less than that of Boron Carbide. DuraShock™ effectively combines the advantages of both while minimizing the disadvantages. With DuraShock™ the performance is comparable to that of Boron Carbide for a price more indicative of Silicon Carbide.

- Steel vs ceramic armor, what are the benefits?

There are differing factors when comparing steel and ceramic body armor. Below is a list of some of the benefits and draw backs of ceramic armor in comparison to steel:

Benefits

- Lightweight – ceramic plates weigh considerably less than steel and in some cases the weight can be halved

- Ceramic armor protects against high-caliber weapons whereas as steel is vulnerable (NIJ Lever 4 AP M2 or similar)

- Increased flexibility of ceramic armor which increases effectiveness in combat situations

- Ceramic armor is more stable than steel meaning its easy to store without worrying about armor degradation

- Steel armor tends to cause ricochet and is shrapnel prone both of which is not found with ceramic armor

Drawbacks

- In most cases after cermic armor has suffered an impact it cannot be used again and is more brittle than steel

- Steel has a longer lifespan when compared to ceramic armor

- Steel armor is usually cheaper