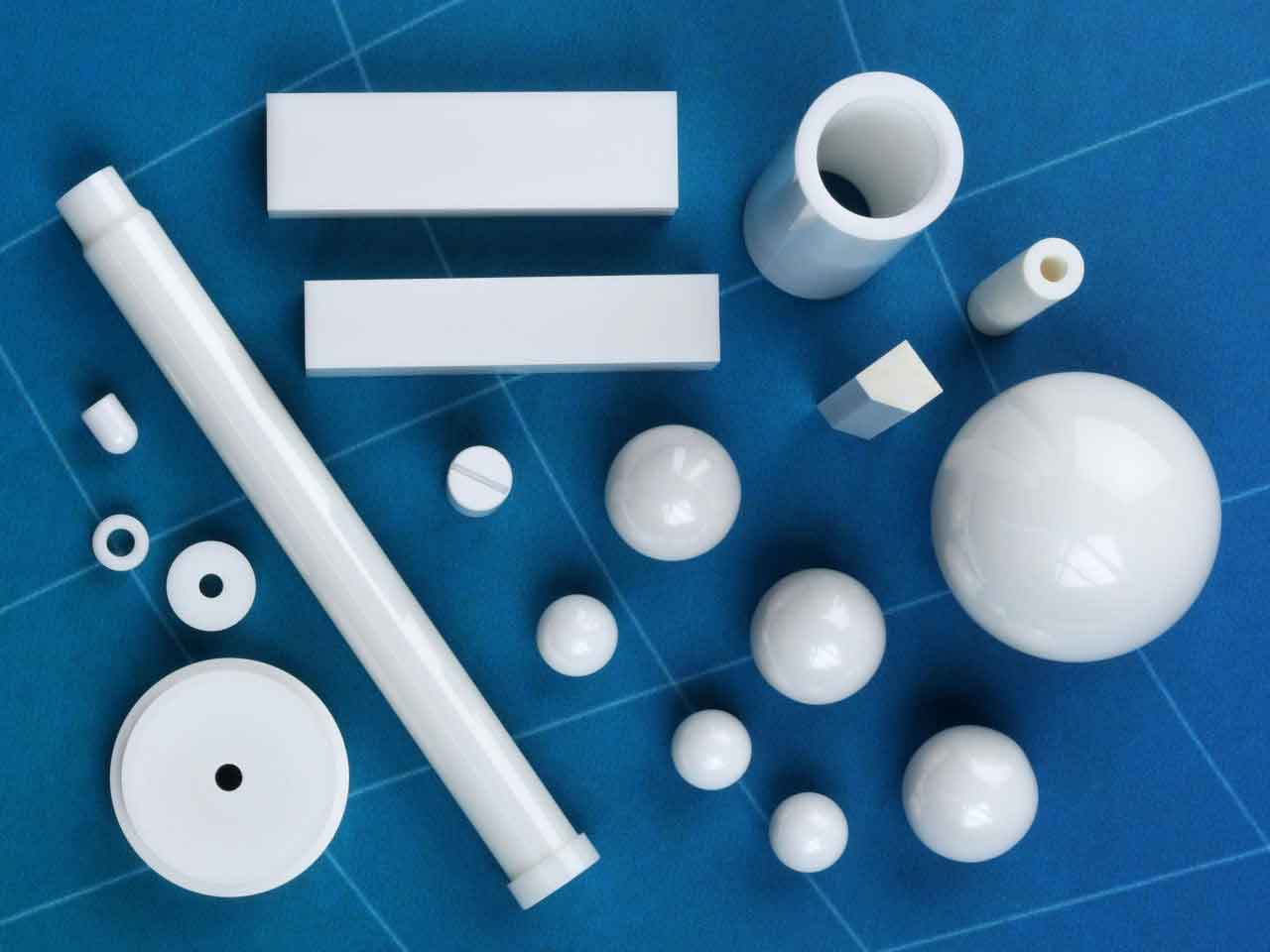

Zirconia Toughened Alumina (Zr-Al2O3) – CeramAlloy™

Material Advantages

- High performance Zirconia Toughened Alumina ceramic composite

- Use temperatures up to 1,500°C

- Chemical inertness

- Excellent wear resistance

- High bending strength

- High fracture toughness

- Excellent balance between bending strength, hardness and fracture toughness

- Sintered to near theoretical density or Hot Isostatic Pressed for enhanced reliability

- Increased tolerance to hydrothermal ageing

Applications

- Rollers and guides for metal forming

- Thread and wire guides

- Metal extrusion dies

- Deep well down-hole valves and seats

- High pressure equipment – ball valve balls and seats particularly suitable for high flow/abrasive fluids

- Focusing nozzles for abrasive media

- Ultra high pressure pumping elements

- Shaft bearings/bushings

Material Grades

We have produced two variations of Zirconia Toughened Alumina which are CeramAlloy ZTA and CeramAlloy Ultra Hard. The differing methods used to produce these materials resulted in slightly different properties and characteristics. We evaluate the similarities, differences and properties of each material and it’s applications on this page.

CeramAlloy ZTA

General Properties

CeramAlloy ZTA is a high performance ceramic composite. This unique ceramic material exhibits a combination of high hardness, strength, wear and corrosion resistance characteristic to their Alumina component while still maintaining reasonably high fracture toughness specific to its Zirconia component.

Applications

- High pressure equipment – ball valve balls and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Deep well down-hole valves and seats

- Shaft bearings/bushings

CeramAlloy Ultra Hard

General Properties

CeramAlloy Ultra Hard is a high performance ceramic composite. This unique ceramic material exhibits a combination of high hardness, strength, wear and corrosion resistance characteristic to their Alumina component while still maintaining reasonably high fracture toughness specific to its Zirconia component.

Applications

- High pressure equipment – ball valve balls and seats – particularly suitable for high flow/abrasive fluids

- Focusing nozzles for abrasive media

- Ultra high pressure pumping elements

- Deep well down-hole valves and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Metal extrusion dies

Material Properties

General Properties

Composition

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Color

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Mechanical Properties

Density

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Young's Modulus

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Fracture Toughness

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Poisson's Ratio

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Compressive Strength

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Flexural Strength

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Hardness (Vickers 500g)

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Thermal Properties

Max Use Temp

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Coefficient of Expansion

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Thermal Conductivity, 25°C

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Thermal Shock Resistance ΔT

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

* Coefficient of Thermal Expansion (CTE) describes how the size of an object changes with a change in temperature.

Electrical Properties

Dielectric Strength

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Volume Resistivity @ 25°C

Unit

CeramAlloy ZTA

CeramAlloy Ultra Hard

Disclaimer: The values presented are mean and typical of those resulted from test samples. They are provided as an indication only to serve as guidance in the design of ceramic components and are not guaranteed in any way. The actual values can vary according to the shape and size of the envisioned component.

Datasheets

Zirconia Toughened Alumina

CeramAlloy Ultra Hard

Zirconia Toughened Alumina

CeramAlloy ZTA

CeramAlloy Material Machining

CeramAlloy can be machined in green, biscuit, or fully dense states. While in the green or biscuit form, it can be machined relatively easily into complex geometries. However, the sintering process that is required to fully densify the material causes the CeramAlloy body to shrink approximately 20%. This shrinkage means that it is impossible to hold very tight tolerances when machining the CeramAlloy pre-sintering.

In order to achieve very tight tolerances, fully sintered material must be machined/ground with diamond tools. In this process a very precise diamond coated tool/wheel is used to abrade away the material until the desired form is created. Due to the inherit toughness and hardness of the material, this can be a time consuming and costly process.

China Ceramic Parts is your machining specialist for your advanced ceramic prototyping & manufacturing needs. We are always happy to use our many years of advanced ceramics experience to provide advice on materials, design, and application. If you would like to buy CeramAlloy plates, rods, tubes or custom machined components, please contact us and one of our experts will be happy to assist you.

CeramAlloy Ultra Hard Video

In this short demonstration video we compare the wear characteristics of Alumina and CeramAlloy Ultra Hard by using a sandblaster to erode a hole in the ceramic plates.

After 15 minutes of sandblasting, it is clear from the results that CeramAlloy Ultra Hard is the better choice for applications of extreme wear but also where a high resistance to fracture is also required.

Frequently Asked Questions

- What can Zirconia Toughened Alumina ceramic (CeramAlloy) be used for?

- Wire forming/drawing dies

- Insulating rings in thermal processes

- Precision shafts and axles in high wear environments

- Wear resistance pads

- Sandblasting nozzles

- Refractory material

- Extrusion dies

- Bushings and caps

- Fiber optic ferrules and sleeves

- Bearings & rollers

- Welding nozzles & pins

- Laser parts

- Electric insulator

- Ceramic guiders

- Medical and surgical component

- Mechanical seals

- Pumps, pistons, and liners

- What's the difference between Zirconia, Alumina, and Zirconia Toughened Alumina (CeramAlloy)?

While Zirconia has the highest fracture toughness of all the oxide monolith ceramic materials, Alumina is one of the most cost effective ceramic materials yet exhibiting very high hardness, thermal stability and favourable electrical properties. CeramAlloy ZTA is a composite material based on Alumina and Zirconia and therefore combining to a certain extent the favourable properties of the two main constituents. So CeramAlloy ZTA will retain the very high hardness of Alumina but also show an increase in fracture toughness and bending strength owing to its Zirconia component so a true “best of both worlds”.

- What are the properties of Zirconia Toughened Alumina (CeramAlloy)?

The following are some general properties of CeramAlloy ZTA ceramic.

- High density – up to 4.1 g/cm^3

- High flexural strength and hardness

- Good fracture toughness – moderate impact resistant

- High maximum use temperature

- Wear resistant

- Good frictional behaviour- favourable coefficient of friction

- Electrical insulator

- Corrosion resistance in acids and alkalis

- What is Zirconia Toughened Alumina ceramic (Ceramalloy)?

CeramAlloy ZTA is a composite material based on Alumina and Zirconia and therefore combining to a certain extent the favourable properties of the two main constituents.